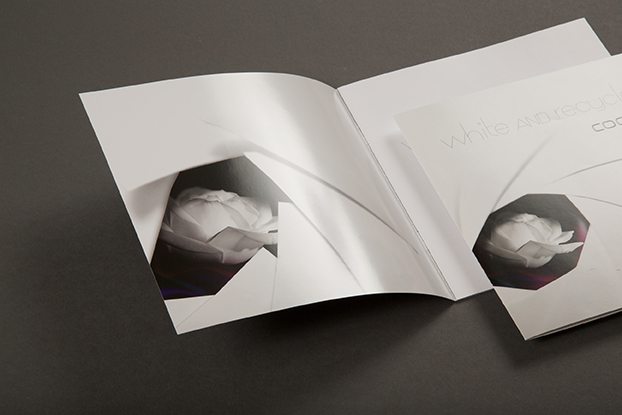

Cocoon Gloss 100

Cocoon Gloss is our gloss -coated, 100% recycled paper that’s FSC® Recycled certified. With excellent runnability, printability and whiteness (CIE 126), it meets the same performance standards as non-recycled papers with ease. And with an exceptionally high-quality glossy surface, printed images are brought to life beautifully.

Made from 100% FSC® Recycled pulp, Cocoon Gloss supports your CSR commitment by recycling and reusing post-consumer waste paper. This means less waste to landfill, a reduction in greenhouse gas emissions, water and energy, and no wood as a raw material. Better all round.

Suitable Applications

In the right grammage, Cocoon Gloss 100 is ideal for:

Report and accounts, glossy brochures, glossy leaflets, direct mail, books (gloss finish), catalogues, luxury gloss magazines, greeting cards, invitations, menus, business cards and posters (depending on required opacity).

Key Features

| Finish | Coated, Gloss |

| Recycled content | 100% |

| Whiteness | Extra white |

Available grammages

- 115

- 130

- 150

- 170

- 200

- 250

- 300

- 350

Printing compatibility

- Sheet Wet Offset

- Sheet Dry Offset

- Cold Set Web Offset

- Flexography

- Screen Printing

- Digital HP Indigo

- Digital Dry Toner

- Laser Personalisation

Mill certifications

- FSC ®

- FSC ® Recycled

- ISO 9001

- ISO 14001

- ISO 50001

- OHSAS 18001

Product certifications

- EU Ecolabel

- Listed WWF Check Your Paper

- Process Chlorine Free (PCF)

- HP Indigo

- Toy Safety

- Archive suitable (DIN 6738)

- Reach Compliant

- Heavy Metal Absence

- Environmental Information

- Technical information

- Printing recommendations