Satimat Green

Satimat Green is part of our new generation of premium, wood-free, coated papers that utilise a high percentage of recovered fibres. As well as being a smooth, silk-coated paper with excellent runnability, printability and whiteness (CIE 124), Satimat Green offers a fast drying time, very good bulk and excellent opacity for heavy ink loads.

Made from 75% recycled pulp and 25% FSC® virgin fibre, Satimat Green uses waste that may otherwise be sent to landfill, reducing greenhouse gas emissions as well as the amount of water, energy and wood needed for production compared to virgin fibre paper.

Suitable Applications

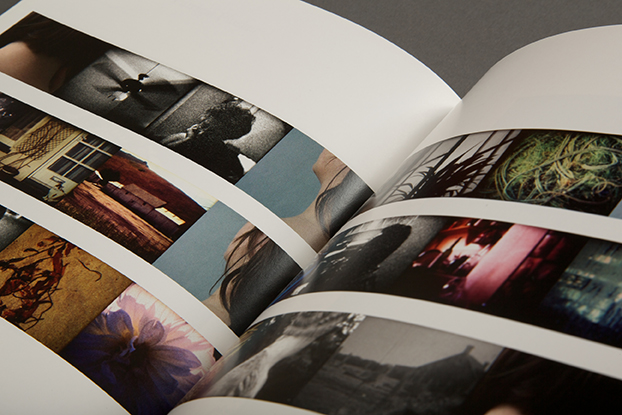

Satimat Green is ideal for:

Reports and accounts, brochures, leaflets, direct mail, books (silk finish), catalogues, luxury magazines, greeting cards, invitations, menus, business cards, posters (depending on required opacity) and to manufacture envelopes.

Key Features

| Finish | Coated, Silk |

| Recycled content | 75% |

| Whiteness | Extra white |

Available grammages

- 100

- 115

- 130

- 150

- 170

- 200

- 250

- 300

- 350

- 400

Printing compatibility

- Sheet Wet Offset

- Sheet Dry Offset

- Heat Set Web Offset

- Cold Set Web Offset

- Flexography

- Screen Printing

- Digital HP Indigo

- Digital Dry Toner

- Laser Personalisation

Mill certifications

- FSC ®

- FSC ® Mix

- ISO 9001

- ISO 14001

- ISO 50001

- OHSAS 18001

Product certifications

- EU Ecolabel

- Listed WWF Check Your Paper

- Elemental Chlorine Free (ECF)

- HP Indigo

- Toy Safety

- Archive suitable (DIN 6738)

- Reach Compliant

- Heavy Metal Absence

- Environmental Information

- Technical information

- Printing recommendations